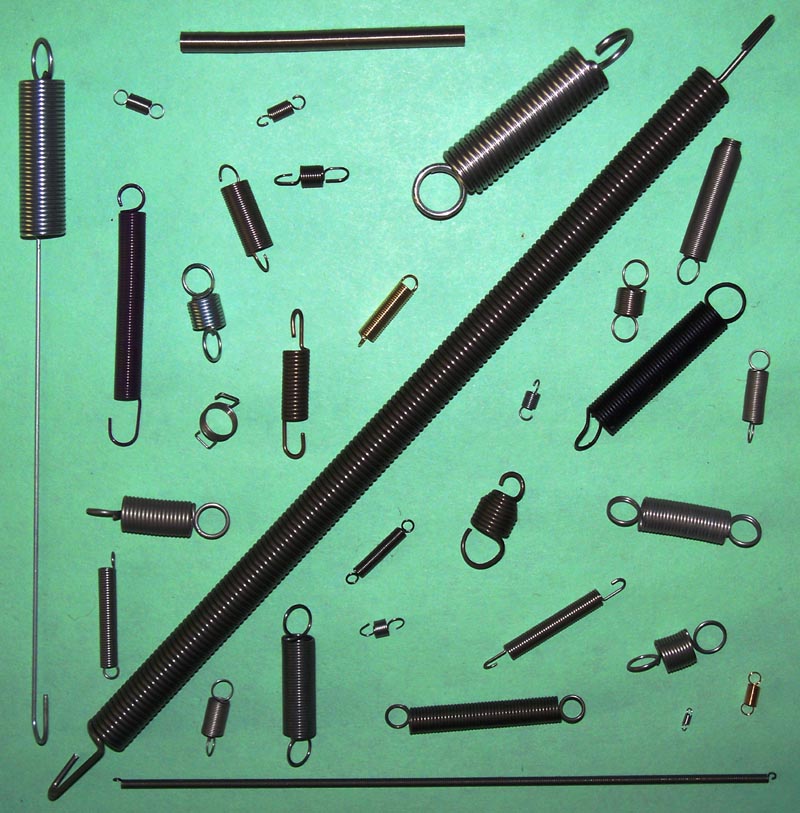

Extension Springs

Extension springs are needed in many applications in which coils must stretch to store energy, provide resistance to a pulling force, or provide a restoring force. They are usually close wound, meaning that each coil is held tightly against adjacent coils. The force holding them together is called "initial tension." Initial tension must be overcome by a stretching force before the coils will open up.

The D.R.Templeman Company is unique in the world of extension springs manufacturers, especially when it comes to very small extension springs. To learn more about our unique capabilities, click the buttons below:

Some uses of extension springs include:

- Storing and releasing energy (e.g., a trampoline spring)

- Returning a component to its initial position after a force has been applied and released (e.g., throttle return springs)

- Providing steady pressure (e.g., windshield wiper blade springs)

- Resisting applied force (e.g., flow meter springs)

Extension springs are commonly produced with either open hooks or closed loops on the ends so they can be connected to other components. As spring manufacturers, we can produce a wide range of end configurations to meet many different connection requirements. Extension springs can also be made with open wound coils for applications that require zero initial tension, or in situations in which the spring needs to function as both an extension spring and a compression spring.